Progress continues after a bit of a fight with my 3d printer. It kept randomly shifting layers over on me and ruining prints. I was able to ascertain (thanks to Maria, with her quick thinking) that the voltage in my house where I had the printer hooked up for cleaning and maintenance was a bit screwy, which caused the motors to occasionally be undervolted and fail to move far enough. Once it was relocated, it started behaving itself again.

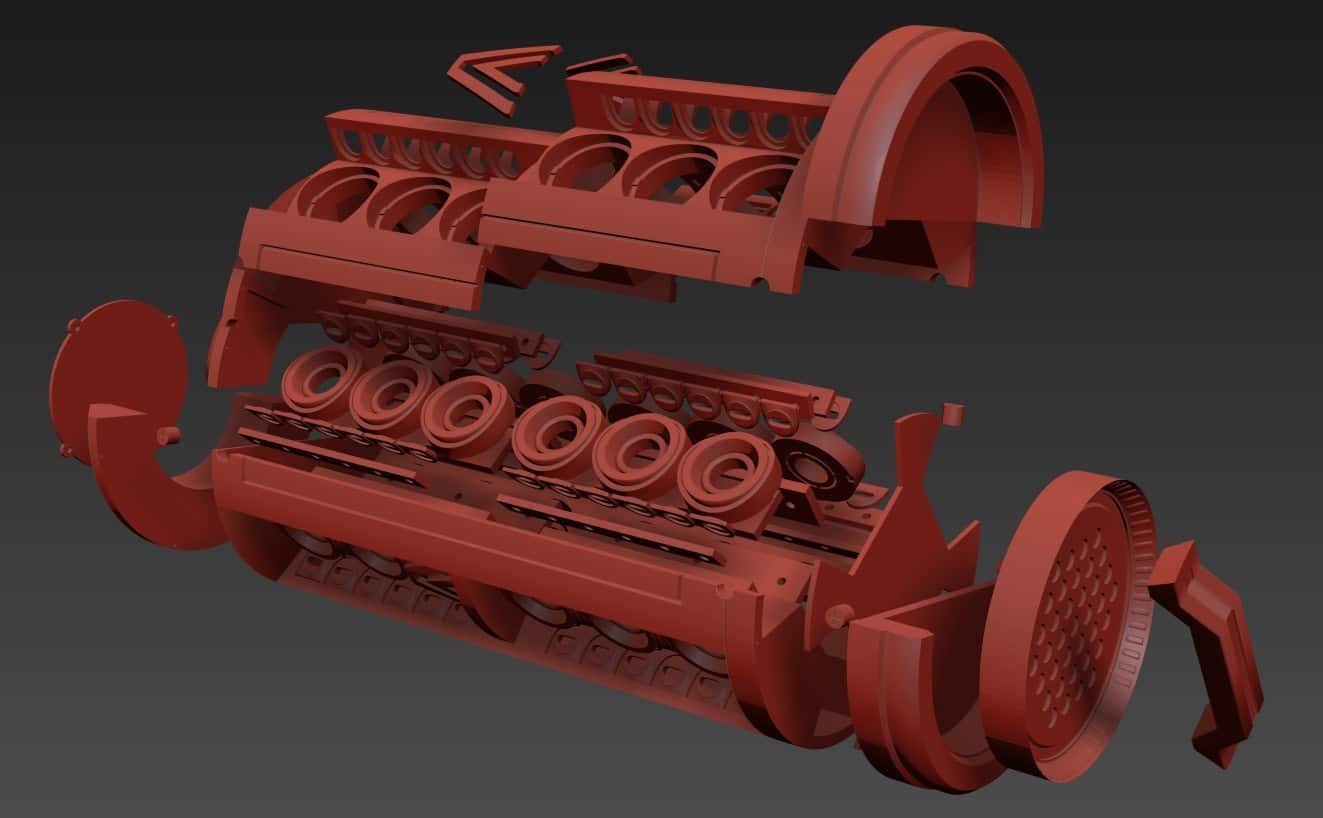

I got one half of the 3d printed handle done, and used a bit of XTC-3D on the blade I’ve already printed out to give it strength and smooth things out a bit. I’m pretty happy with how the handle’s fittings seem to be coming. A quick test fit of the components shows that everything is just about the right size, give or take just a little bit of sanding.

As an aside, I’m really impressed with the support structures Simplify 3D makes for printing. They do a great job and come out real easy.

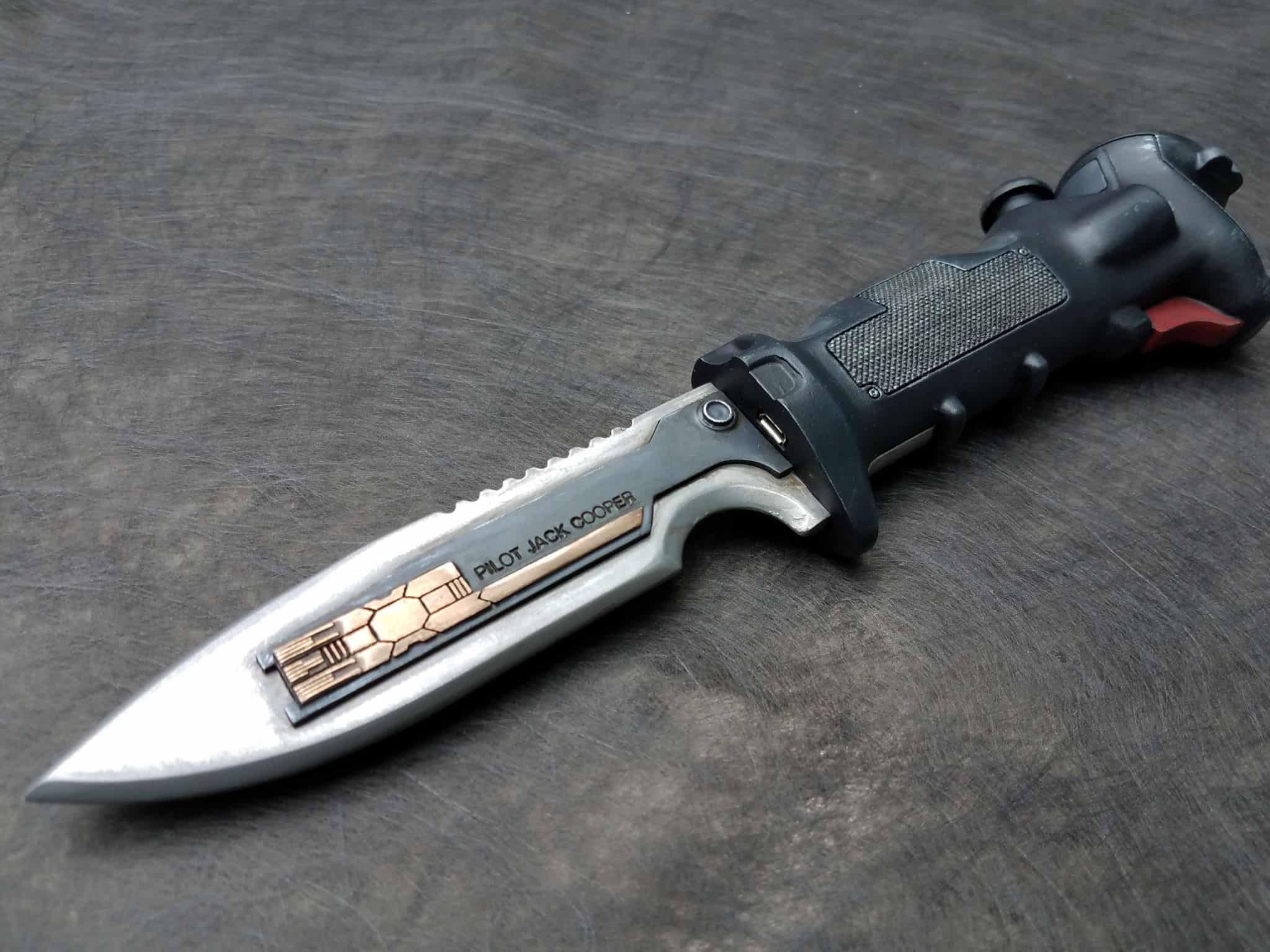

The other half is printing now. More importantly, however, is the fact that today I got to play with a laser engraver and cutter! The local university has a big, beefy unit and since Maria is a student there and knows some people, I was able to lean on her for a favor or two and get access to their machine. They were kind enough to etch a dial for the handle in the display for me that I think looks pretty damn cool.

Sorry about the poor quality photos, but I’ve been in a hurry most of the day. I’ll be honest and say I wish the text (the “255” that displays when you complete a hack with the knife) were more legible, but I could only lean on the kindness of the university staff before they kicked me out.

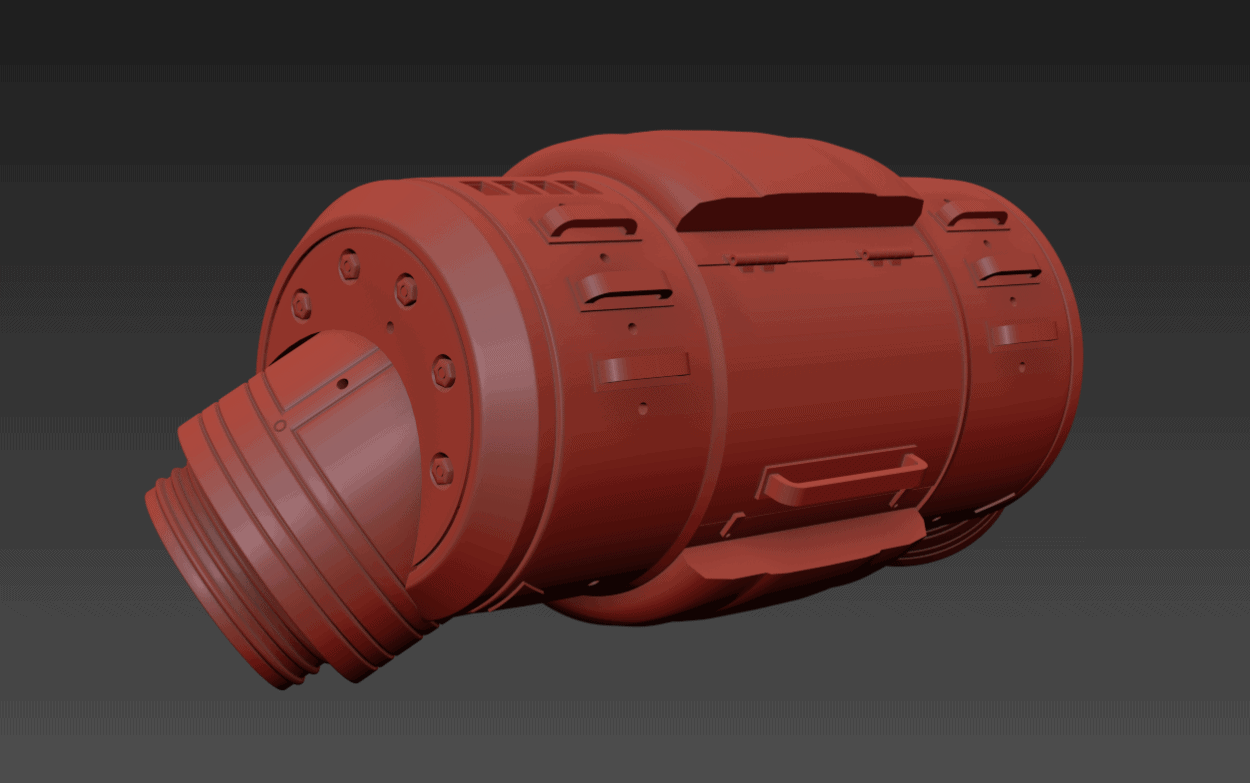

The final version, as I envision it, is to have the 5 LEDs slotted behind the disc, diffused on the back with a bit of sanding, and spinning in a radial fashion. Hoping it’ll be a neat effect, but even if it doesn’t work as intended, it’s still better than nothing.